Here is where additional info will be posted for the project. Currently all info that I do have is in the below-pasted proposal, and past experience designing or building computer cases.

Seed Grant Proposal

Computer Case Project

What is It?

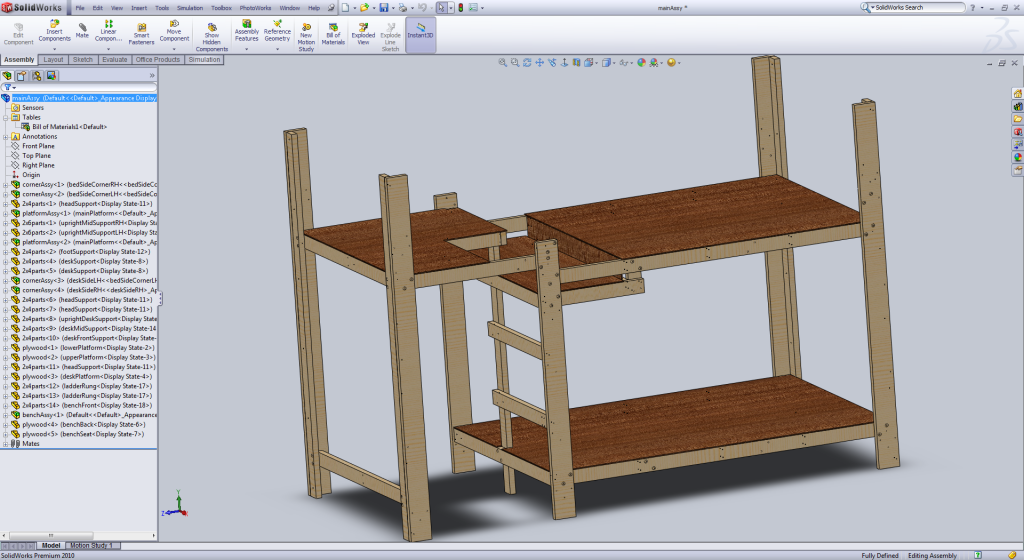

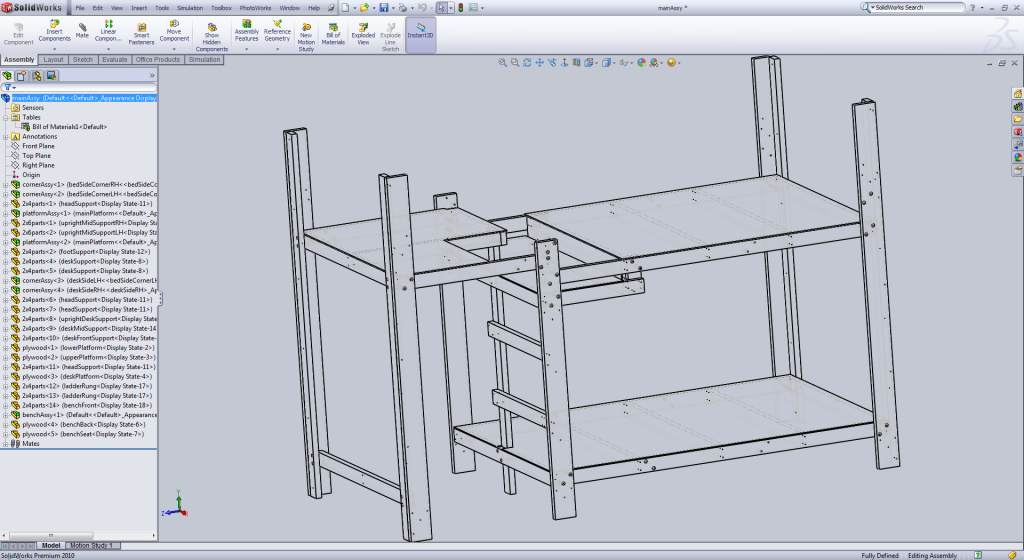

The computer case project is just that, a case that will be laser cut from Lexan that will house a minimal computer, (m-Atx motherboard and smaller) with the intention of being an attention-grabbing set-top box/front-end for a media setup.

Origin:

This project is actually not original, but was inspired by a project I stumbled across on Ponoko (a mail order laser cutting service) that was submitted by another user (project page here: http://www.ponoko.com/design-your-own/products/mini-itx-computer-2078). This immediately struck me as a (fairly) unique case that can be modified and personalized by the user. This along with the design challenges of organizing and anchoring the components in a logical manner are what fuels my motivation.

Design and Considerations:

I have designed lexan cases in the past, however have never actually built one. The limited factor was indeed the cost of the laser cutting service. I will have to design this case from scratch, but have worked extensively with computer components, so it will not take long. Some considerations that I will take into account include: ample cooling, and slide in assembly/mounting of drives.

The case will probably hold the following: m-Atx motherboard/cpu/RAM, a power supply, an SSD OS drive, an HDD high capacity storage drive, a slim ODD, and several case mounted fans.

Skills Needed:

The skills needed to build this project include a knowledge of SolidWorks or another CAD package in order to construct the model. I will also need to make sure I am taking accurate measurements of the components. All told, intelligent design will be the most important skill, and basic assembling will be secondary.

Bill of Materials:

| Item | Store | Approx Unit Price | Qty | Total |

|---|---|---|---|---|

| Acrylic (colored) | (open to advice) |

$30 |

4 (24”x24”) |

$120 |

| Assorted Hardware | Home Depot |

$15 |

– |

$15 |

|

Total |

$135 |

Goals and Scope:

The goal of this project is to have a complete case before the end of the semester. Ideally it would be done far before that. I would estimate the cutting time to within a few hours, and the assembly time to something similar. The bulk of the time to be put into this project is in the design of the case. It is entirely possible for me to design this case over the next few weeks and have it ready to go beyond that. Another benefit to this project is that I can make my files available to anyone who is interested duplicating the project, or possibly even working with someone who would like to adapt the idea to their own setup (or a computer in the lab!).

More Information:

More information is be available upon request, and may be available (if I have time to put it up…) at http://unrulyrecursion.com/press/2012/03/computer-case-project/